PRINT: PrinterPrezz Developing 3D Printed Innovations

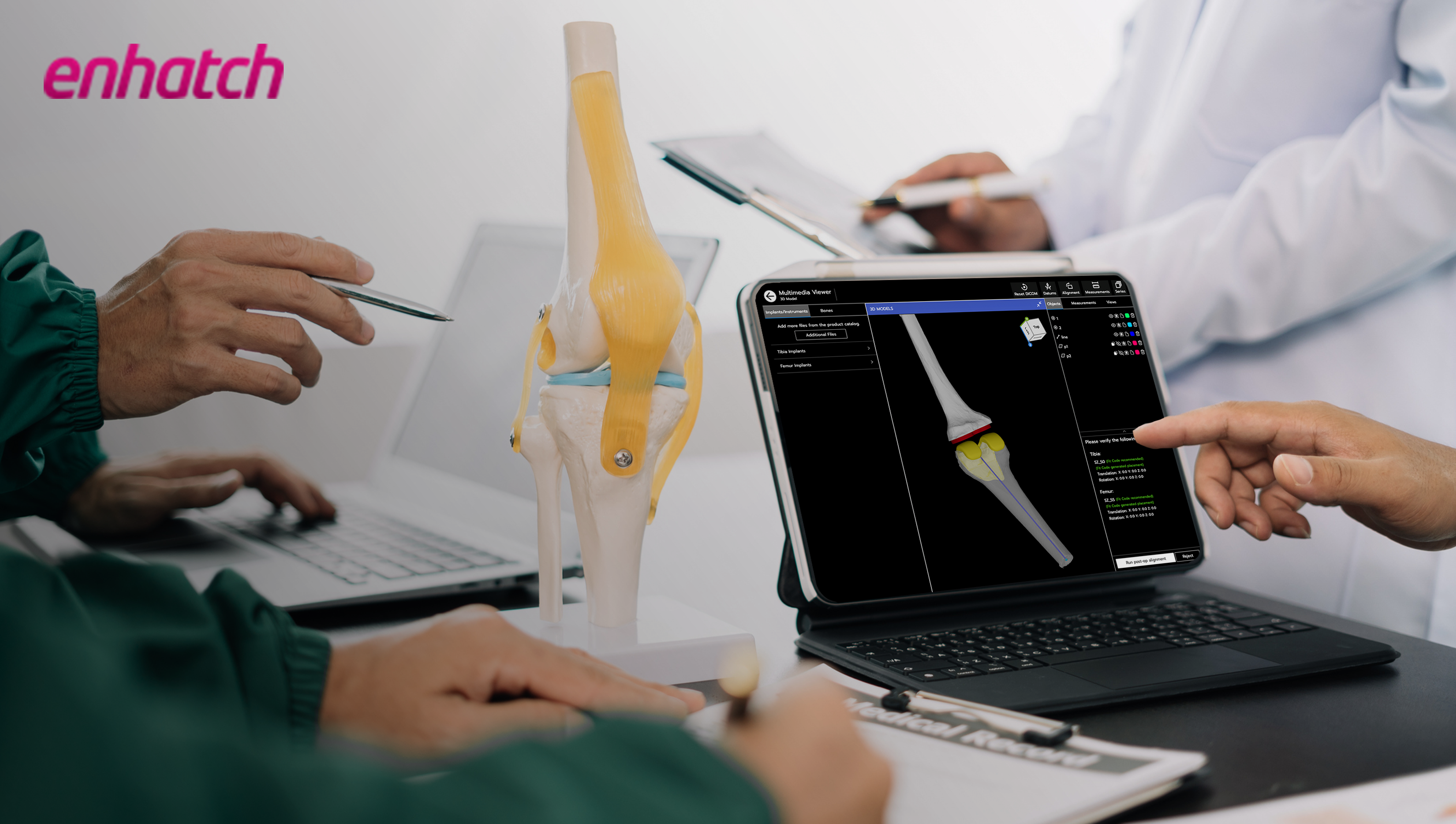

During the NASS 2021 meeting, Enhatch interviewed leaders working in top health tech companies about their work and how it impacts the Intelligent Surgery Ecosystem. In this interview Ecosystem Specialist Ashley Porto sat down with Scott Zafiropoulo and Brad Coale from PrinterPrezz.

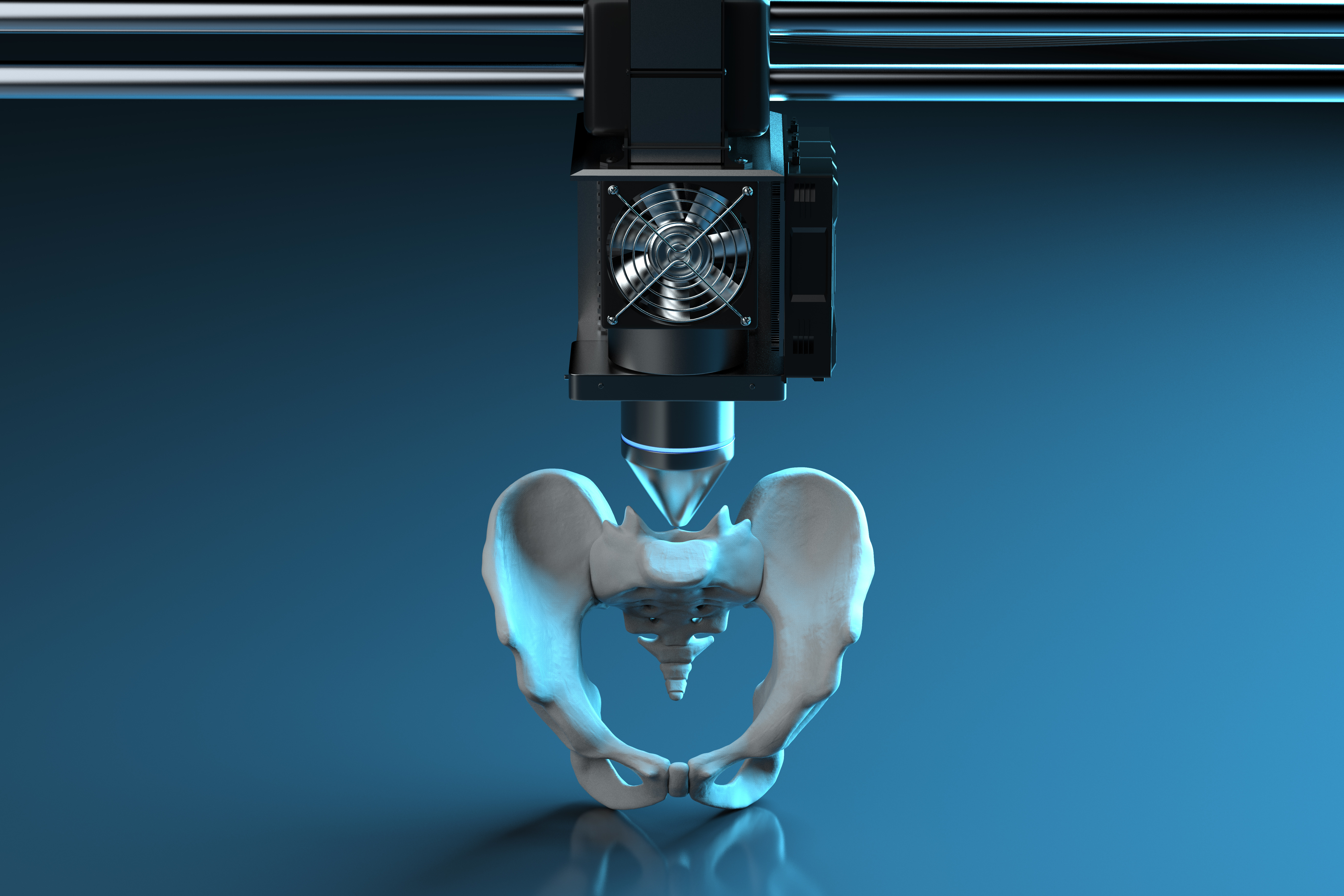

With a focus on combining 3D printing with nanotechnologies, PrinterPrezz is streamlining production for spine device companies. Since starting in late 2017, this startup has grown to around 30 employees and is in the process of raising their Series B funding. While 3D printing isn’t a new concept, it is new to spine and orthopedics companies but may soon become part of normal practice.

“Some people from the industry and technology area in Silicon Valley and two surgeons from UCSF got together and created the company to utilize 3D printing and advanced technology to bring solutions to the medical industry,” says Brad Coale, Head of Product Development at PrinterPrezz.

While the industry has suffered from supply chain problems for decades, PrinterPrezz still works to get potential customers comfortable with the concept of using 3D printed materials.

“I see a lot of people that talk about it. Not a lot of people actually follow through with it,” says Scott Zafiropoulo, senior vice president of PrinterPrezz. “That's where I think there's going to be a few key contributors in the industry that start to push some of that narrative that aren't afraid of being uncomfortable and getting into new space.”

Embracing change and new technology can be an uphill battle, but it’s something that PrinterPrezz is willing to take on. Repairing the supply chain process in the medical device industry will not only reduce costs, but will help prevent some delayed surgeries.

“Change needs to be there and I don't think I'm seeing it right now,” says Zafiropoulo. “There's a lot of status quo, people need to be able to start embracing some difference.”

“I don't think I've seen a lot of changeover in the last 10 years plus,” says Zafiropoulo. “It's still a slew of trays that get brought to a room and a couple of tables, or at least one full table, in the back of an OR that's already crowded, just full of stuff. And a lot of it never even gets used so different ways to be able to package and deliver a product. And instrumentation is where we're going to start seeing, hopefully, some new change.”

With an industry holding a reputation for being slow to adopt new technologies, the pandemic presented interesting challenges for PrinterPrezz. But, with determination and innovation, the 3D printing company quickly adapted and rose to solve a different problem that healthcare was facing.

“The one thing that I think was good about our company, we actually responded and made PPE,” says Zafiropoulo. “A lot of other companies tried to just continue with regular business. We kind of all hands on deck dropped and kind of shifted to try to help the industry in general. We have a lot of connections to the local hospitals, so we joined in where we could.”